Smartphone Biosensor

We developed a smartphone-based optical rapid test with the goal to establish the technology as a versatile platform for patient-oriented diagnostics. The sensor principle relies on surface plasmon resonances (SPR) and planar-optical polymer waveguides. The realized system can be operated by a smartphone and uses its light source (flash light) for illumination and the camera for detection. It is designed to detect various biomarkers relevant for human health or well-being. For example, the system was applied for the detection of the diagnostic biomarkers CRP (C-reactive protein, inflammatory marker) and BNP (B-type natriuretic peptide, cardiac marker) or of Vitamin D. It can analyze substances in the liquid state, i.e. from blood, saliva, or sweat samples. In future, the platform will be extended towards detection of several biomolecules simultaneously (multiplexing) with high sensitivity and specificity. It is supposed to be operated by trained personnel in clinics as well as by non-experts, i.e. the users themselves, for self-monitoring at home.

Please contact: Prof. Dr. Bernhard Roth

©

HOT

©

HOT

Please note that activating the video will result in the transfer of data to the respective provider. Further information can be found in our privacy policy.

Play video

Lensless Microscope

Lensless holographic microscopy is a revolutionary technique pushing the boundaries of microscopy. Unlike traditional microscopes that rely on complex lens systems for image magnification and resolution, this technique operates without lenses. Instead, it is based on a combination of microelectronic chips, such as camera chips and microLED chips, and holographic computation. This innovative technology offers an impressive optical resolution of 700 nm and an expansive field of view, determined by the size of the camera chip. This makes it particularly suitable for bioscientific research, especially for long-term observation of cell cultures, even under the challenging conditions of an incubator with high temperatures and humidity. Moreover, lensless holographic microscopy enables microscopic analysis with compact, everyday hardware, making it widely accessible. A promising future application could be point-of-care medical analysis, which may support cost-effective healthcare in an aging population.

The development of these basic optical technologies led to the founding of a start-up, QubeDot GmbH. QubeDot is now transferring these technologies into applications and was awarded the European Innovation Council's high-ranking EIC Accelerator Grant in 2024.

Please contact: Prof. Dr. Andreas Waag

Please note that activating the video will result in the transfer of data to the respective provider. Further information can be found in our privacy policy.

Play video

GPU-based Holographic Display

With the ever more increasing demand for head mounted devices that are both lighter and have higher fidelity, both in terms of spatial resolution and contrast, current generation display technology quickly reaches a physical limit imposed by the wave optical properties of light. We make use of this property by designing algorithms that directly generate phase modulating holographic images that generate the target visuals through diffraction effects. This enables outputting three dimensional visuals with real depth of field and parallax perception.

This is made possible by simulating the wave-like propagation of light in a physically accurate way. We develop extremely fast algorithms that run in single digit milliseconds allowing for the creation and combination of multiple holograms at real time framerates, further increasing the visual quality.

Our physical setup allows both verification and optimization through iterative Camera-In-The-Loop methods.

Please contact: Prof. Dr.-Ing. Marcus Magnor

Optical Neuromorphic System

In neuromorphic computing systems, the structure of biological neuronal networks, in particular the massively parallel networking of neurons, is modelled by hardware. This demonstrator realises the parallel connections in optics, whereby the use of microLED arrays based on gallium nitride enables a particularly efficient conversion of the electrical activations into optical signals. A data set of handwritten digits is classified to demonstrate the functionality.

Please contact: Prof. Dr. Andreas Waag

Miniaturized Quantum Key Distribution System

Quantum technologies nowadays are enabling a new type of secure communication. In order to pave the way for this pioneering technology for widespread application, an interdisciplinary team in the PhoenixD Cluster of Excellence is developing, manufacturing and demonstrating a micro-optical transmitter for so-called quantum key distribution. Modern optics manufacturing techniques are used, including pick and place of micro-optics with active alignment, ion beam sputtering, selective laser etching and direct laser lithography.

Please contact: Prof. Dr. Michael Kues

Please note that activating the video will result in the transfer of data to the respective provider. Further information can be found in our privacy policy.

Play video

Micro Optics Platform

Future photonics relies on miniaturized chips with integrated optical components connected among each other and to the outer world. For the Optical Micro-Platform demonstrator, we combined a laserdiode, photodiodes, and a thin film filter to a functional unit on a glass platform. For wave-guiding, polymer structures can be realized by various manufacturing options, including lithography or direct printing in an inline process. Our platform maintains versatility by functional thin film systems produced with ion beam sputtering and miniaturized by laser separation. Assembly and alignment of the components is possible using our precision optics assembly system.

Please contact: Prof. Dr. Detlev Ristau

Please note that activating the video will result in the transfer of data to the respective provider. Further information can be found in our privacy policy.

Play video

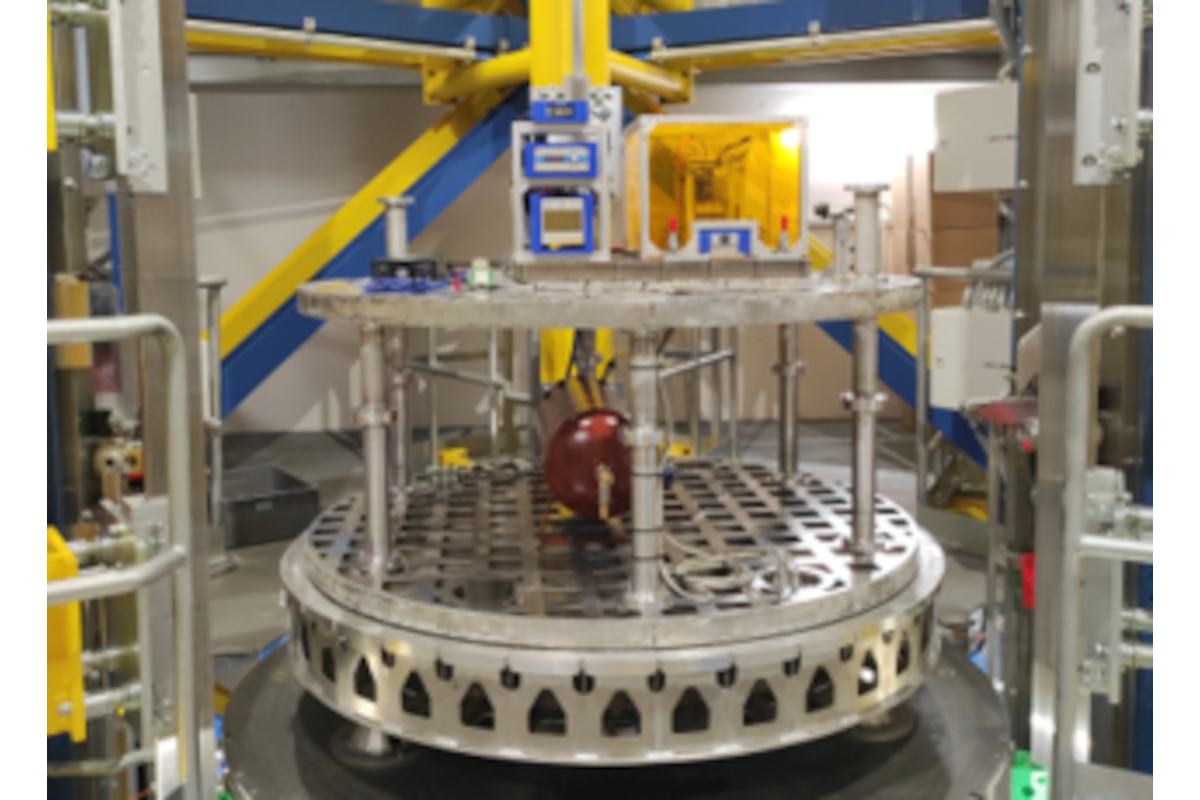

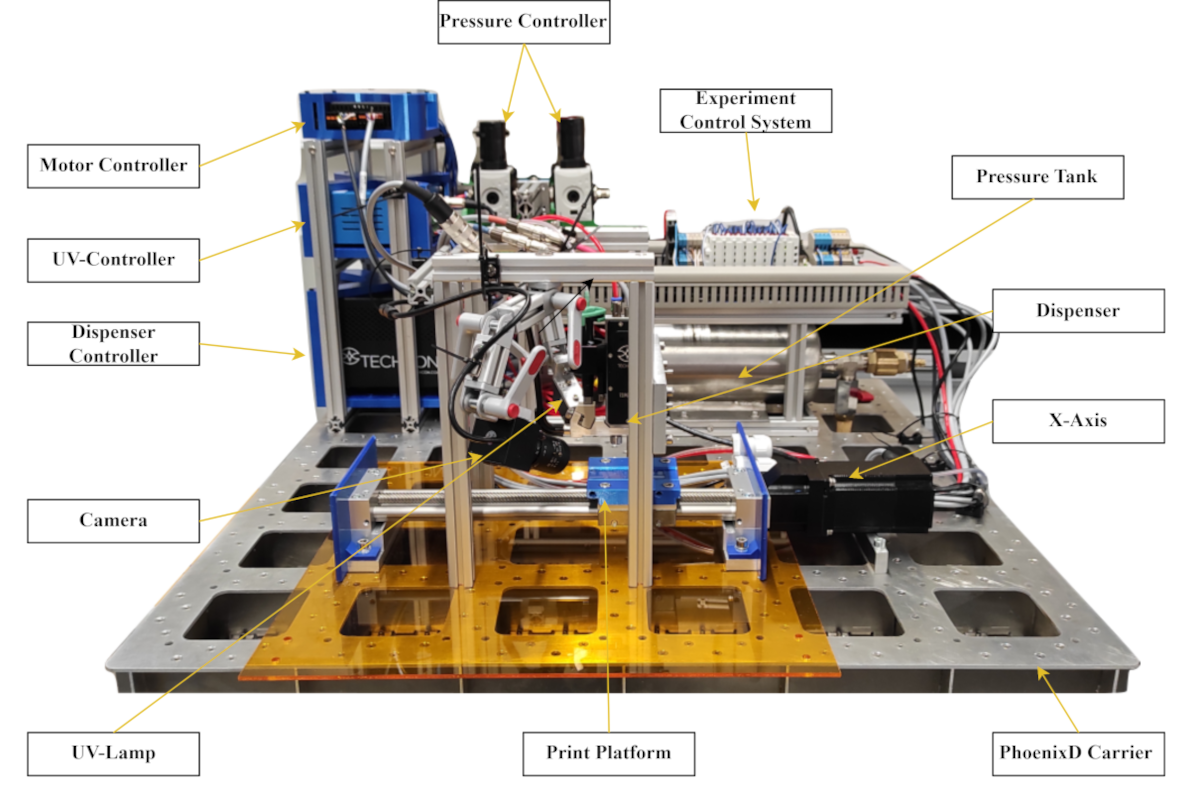

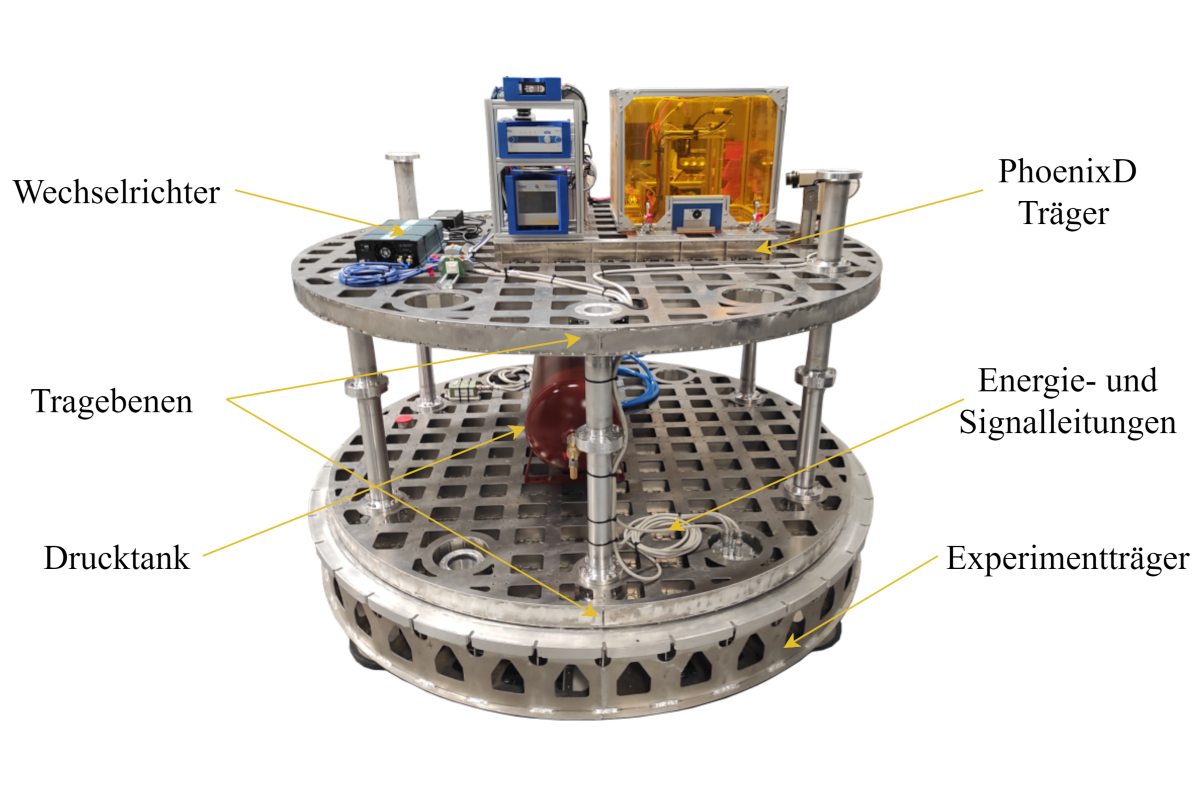

Gravitation as Production Parameter

The Einstein-Elevator offers a globally unique infrastructure for experiments under precisely adjustable gravitational accelerations. In the Demonstrator, microlenses were manufactured under various gravitational conditions, resulting in different geometric dimensions depending on the gravitational influence. The demonstrator interactively illustrates the resulting change in focal length.

Please contact: Dr. Christoph Lotz

Laser-based 3D Printing on the Moon (MOONRISE)

In the MOONRISE project, laser-based 3D printing shall be established on the Moon. The lunar dust called regolith should serve as a building material for shelters, landing pads, and streets by melting it with an intense, mobile laser beam and solidifying into a hard structure. For the first proof-of-concept under lunar environmental conditions, a space-suitable, compact and lightweight laser system is being developed, which will fly to the Moon on a commercial lunar surface mission executed by Astrobotic . The analysis of the fused objects is supported by an in-house developed artificial intelligence.

Please contact: Prof. Dr. Dietmar Kracht

©

LZH

©

LZH

Assembly Simulation with Digital Twin

The digital twin serves as a central interface between real and virtual manufacturing in the multi-stage production of optical elements and the assembly of optical systems. To maximize registration accuracy at various production stations for optical systems, a planar-motor-based, fully integrated axis system is employed. This system manages both the transport between individual stations and the precise alignment movements within the processing stations in an automated production matrix. This reduces the need for additional axis systems, thereby reducing investment costs. The subsystem demonstrates both the achievable precision and the flexible combination of different degrees of freedom at exemplary processing stations. At the same time, the digital twin enables adaptive optimization and real-time correction of processes throughout the entire production chain.

Please contact: Prof. Dr.-Ing. Behrend Denkena

Your contact

30167 Hannover